Not many people think about the inner workings of pens, but woodturners know better. If the parts of a pen aren’t assembled just so, the pen will not work properly. There’s nothing more frustrating than spending many hours turning and finishing a custom pen only to find that when you twist or click, either nothing happens or the ink refill isn’t sitting right in the nib.

My handmade click pen isn’t clicking!

When you turn a click pen and it isn’t engaging the ink refill properly, there are a few things to check that might fix your problem.

- Check the springs. Make sure the spring in the click mechanism is seated down inside the mechanism properly. This spring is located where the button fits into the finial. Also, check that the spring positioned over the refill is sitting right. The small end of this spring goes on first and should slide all the way to the shoulder of the refill.

- Remove debris. Sometimes tiny bits of debris make their way into the pen nib from the plating process, turning or gluing. Debris in this area can interfere with your pen’s function, even if it’s too small to see. Remove the spring from your ink refill, and use the refill to poke through the small hole of the pen nib a few times to try and clear it out.

- Inspect the refill. The refill should be seated snugly into the click mechanism.

Possible reasons your click pen isn’t working

- Assembly: Make sure to use a press block when assembling your pen. Never press on the button using a pen press or a vise because this will break the click mechanism.

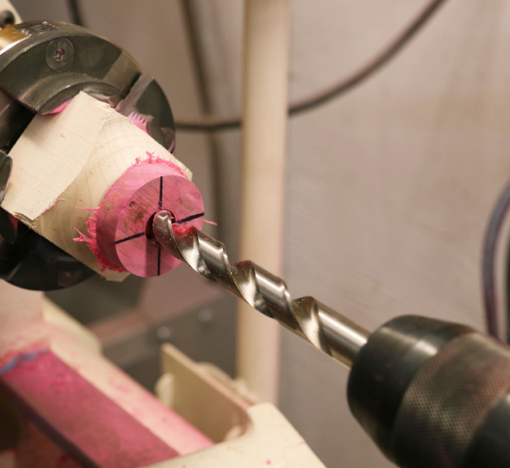

- Pen mill: If clicking your pen pushes the pen body apart, it’s likely that the inside of the pen barrel has been reamed out when using a pen mill. To prevent this, make sure the pen mill shaft is perfectly straight when squaring the ends of the blank. Check that your drill press table is completely level and use a drill centering vise. Using a hand drill is not recommended.

- Tubes: The inside diameter of replacement tubes have very little room for error. If even a small bit is peeled away when making your pen, the hardware will not fit tightly into the tube and your pen might fall apart. Tubes can also be loosened if a pen is assembled and disassembled repeatedly.

Why isn’t my twist pen working?

Before anything else, pull the mechanism out of the pen and try twisting it back and forth on its own.If you have more than one of the same pen kit, try swapping the click mechanism to see if it works. This will let you know for certain whether or not the problem is the mechanism. If everything looks okay, the problem lies elsewhere and you need to do some more investigating.

Here are some common problems with twist pens. Many issues can be remedied by replacing a part or a little extra work.

- The barrel of the pen spins on the mechanism but the ink refill doesn’t come out. The inside of the tube has been reamed out during the end mill squaring process or the raised nubs of the twist mechanism are worn down. Try replacing the click mechanism or getting replacement tubes.

- The ink refill extends too far out of the pen nib when engaged. The tubes are probably too short. This typically happens when squaring off the ends of a pen blank and a tiny bit of the tube is accidentally cut away. When squaring up your ends, go slow and use caution! When using the pen mill and cutter head, draw it back to look at your progress often to avoid cutting your tubes too short.

- The barrel is too short. If you’ve accidentally made the pen barrel too short, all is not lost. Worst case scenario, check our website to see if the same kind of pen is available as a fountain pen. Often, an overturned barrel will work fine for a fountain pen of the same style as their ink cartridge is shorter and there is no room needed for a mechanism.

Can a damaged wood pen be rescued?

You’d be surprised just how long a well cared for pen can last! If you’re unsure whether or not your pen can be salvaged, need spare parts to bring an older pen back to life or just have questions about pen kits and other wood turning supplies, feel free to contact us and ask. All of our staff are at varying stages of the turning journey too, and chances are at least one of us can help you!