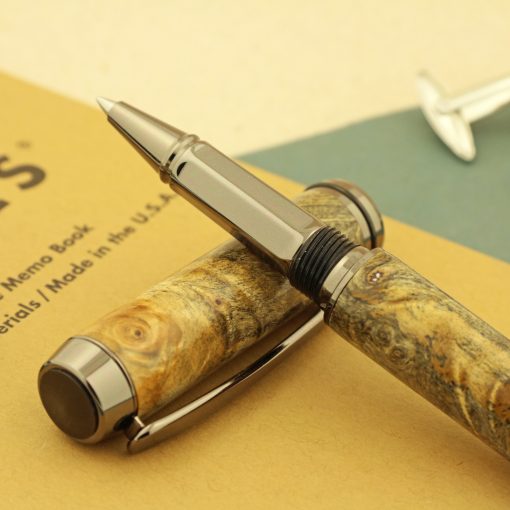

Achieving a flawless finish on your wood turned pens and lathe projects can be a long process that requires patience, attention to detail and many stages of sanding. Wet sanding or using an abrasive paste are two ways to get your pen blanks to that satisfyingly smooth and flawless state.

Sanding with lubricant on a lathe

Wet sanding means using water or lubricant with sandpaper when finishing a wood project. In some scenarios, there are quite a few benefits.

- Dust reduction: Wet sanding significantly cuts back on dust produced from dry sanding. This keeps your work area tidy and the air clean, saving your lungs from potential irritants.

- A finer finish: Combining water or lubricant with your sanding process helps prevent clogging and buildup on the sandpaper. It produces a gritty liquid called “slurry”, which fills the pores of the wood, creating smoothness and uniformity that dry sanding just can’t achieve.

- Heat management: The friction between sandpaper and wood can generate heat, which might damage the surface. Wet sanding helps prevent burns and blemishes. Dense species with a tight grain, such as hard maple or oak, are more likely to generate heat. Resinous woods like pine or spruce also tend to get hot fast.

- Reveals imperfections: A wet surface highlights tiny scratches and tool marks that are invisible when dry, allowing you to buff them out before applying a final finish.

How to wet sand a pen blank with water

The most common choices for sanding lubricants are plain water or premixed abrasive pastes. Some woodturners will use their final finishing oil to create a slurry. In this case, the heat generated from friction forces the oil into the pores of the wood.

Many kinds of sandpaper don’t stand up well to moisture, which is why it’s helpful to use Abranet or mesh. They don’t clog easily and can be rinsed out and reused as needed. Wet sanding with water allows you to apply any finish you choose once it’s dry, whereas pastes or oils may not be compatible with certain finishes.

- Turn your blank down to the shape you want and apply the lubricant to the pen barrel generously.

- Start the lathe at a low speed and apply 400 grit mesh or sandpaper until a slurry forms. Use even, gentle pressure but let the slurry do the work.

- When finished with the 400 grit, wipe the slurry from the wood with a paper towel or cloth. Apply more lubricant and proceed with the next grit. You will be able to feel when it’s time to switch.

- Wipe away the slurry in between grits until you reach 1000 grit or the desired smoothness. You can try micromesh sheets if you want to go all the way to 12000. This is useful when turning acrylic or resin.

- Wipe the blank thoroughly and allow it to dry. For added smoothness, proceed with a microfine abrasive paste before applying the final finish.

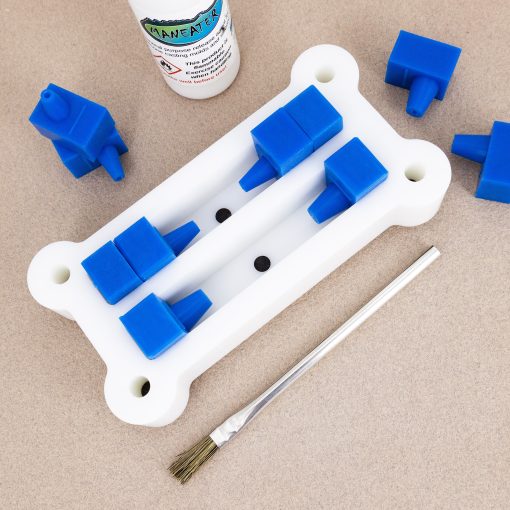

Using an abrasive paste on lathe projects

Combining wet sanding with abrasive pastes can produce superior results in wood turning. Wet sanding smooths the surface, while abrasive pastes add a fine polish.

Abrasive pastes are made of fine particles suspended in a wax or oil base. These particles can include materials like aluminum oxide, pumice or diatomaceous earth which is a type of crumbly sedimentary rock. Abrasive pastes are often used as a final step before finishing with oil, wax, or shellac by creating a smooth and polished foundation. To use an abrasive paste, sand your wood to 1000 grit. Apply the paste generously with a cloth or pad while the lathe is running. Work the paste into the surface to remove fine scratches and imperfections.

You can start with original grit paste followed by microfine paste for best results.

Wet sanding is a game changer for woodturners

Many woodturners swear by wet sanding for dust reduction and the unbeatably perfect finish it creates on custom-made pens. Try out some of our top-tier abrasives and pastes at William Wood-Write, along with our huge selection of exotic wood pen blanks and turning supplies.