If you’re venturing into the world of casting your own resin pen blanks, it can seem like there’s an overwhelming amount of things to learn. You can experiment with almost any material and with practice, create some really unique, visually stunning pieces. One important element of resin casting is choosing the right mold. Molds can be expensive, so it’s worthwhile to make sure you choose the right ones and learn how to maintain them to get the most bang for your buck. With the right care, a silicone pen blank mold can last for years and provide hundreds of castings. Here’s what you need to know when shopping for molds.

Silicone or HDPE molds: Which is better?

Silicone is the most popular material for pen blank molds. Its flexibility makes it simple to just pop out the cured block of resin with the help of mold release spray. While the durable flexibility of silicone makes it very easy to work with, it also calls for some extra precautions. For example, if you put it in a pressure pot that has a curved bottom you must prop it up on something perfectly flat or else you’ll get curved blanks. Silicone molds last a long time with polyester and urethane resins such as Alumilite, but have a slightly shorter life with epoxy resins. Here at William Wood-Write, we use silicone molds for our artisan-crafted resin and hybrid pen blanks.

High-density polyethylene, or HDPE is much harder than silicone. Although it is sometimes dubbed “non-stick”, it’s still recommended that you use a mold release spray. Unlike silicone, which you can bend to easily release a cured pen blank, an HDPE mold must be disassembled or, as with the PSI kit, have a rubber stopper in each chamber that can be removed and the resin punched out through a hole. This kit comes with adjustable silicone tube mounts which allow you to make any size of pen you like. HDPE molds are better for epoxy blocks than silicone. Some pen turners make molds out of plastic cutting boards, which are a similar material.

Resin casting molds for pen turning projects

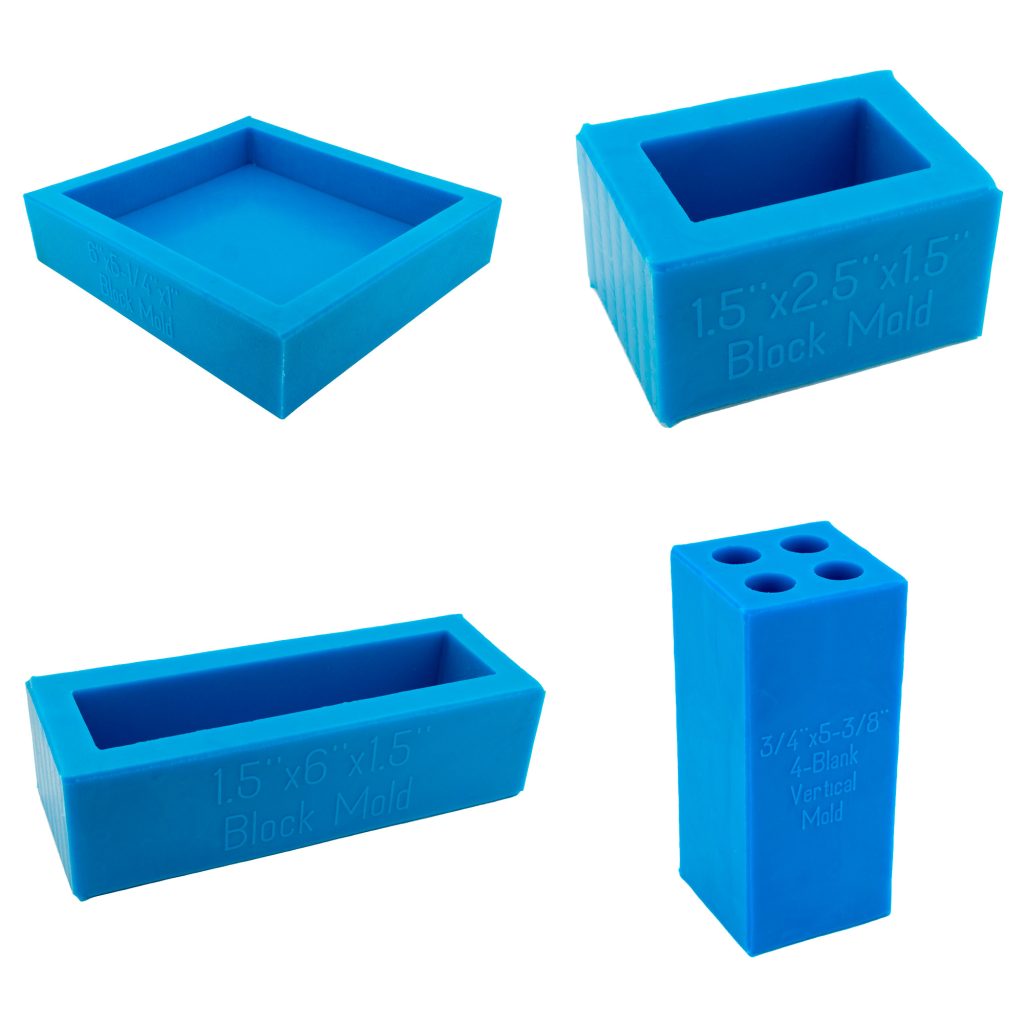

Resin casting isn’t limited to making pen blanks. That’s why you’ll find molds in nearly every shape you can imagine, some of them pretty complex. Fortunately for pen makers and wood turners, our options are a little simpler. There are a few different basic shapes to choose from, depending on what turning project you’ll use it for.

Block Mold: This flat square-shaped mold makes a block of resin that, once cured, can be cut into four pen blanks. It’s great for making multiples of your most popular pen blanks for craft shows or gifts.

Project Molds: The bottle stopper and knife block molds are self-explanatory, but they can be used for more than just those projects. The knife block mold is the perfect size for most kitchen utensils or tool handles you might turn on a lathe, and the bottle stopper mold can be used for ornaments or blocky items like a shaving brush.

Vertical Round Mold: This mold creates four round pen blanks at one time. The round shape makes for quicker turning time, helps prevent wasting resin and is especially suitable for smaller pens like the Slimline.

Rectangle Pen Blank Mold: Available in either four or two chambered options, these molds make the standard sized pen blank of 7/8″ x 7/8″ x 5 1/4″. If you’re selling your pen blanks, this is the size most people are looking for. They’re useful for thicker pens and have room for more inclusions such as wood pieces. HDPE mounts can be put into these universal pen molds to make them longer or shorter.

Tube-in mold: Tube-in molds have a chamber for one or two pen barrels with plugs on either end. The plugs hold the pen tube in place while you pour resin over top. This eliminates the need for drilling or gluing tubes in. These molds often come in pen-specific styles like cigar or Sierra.

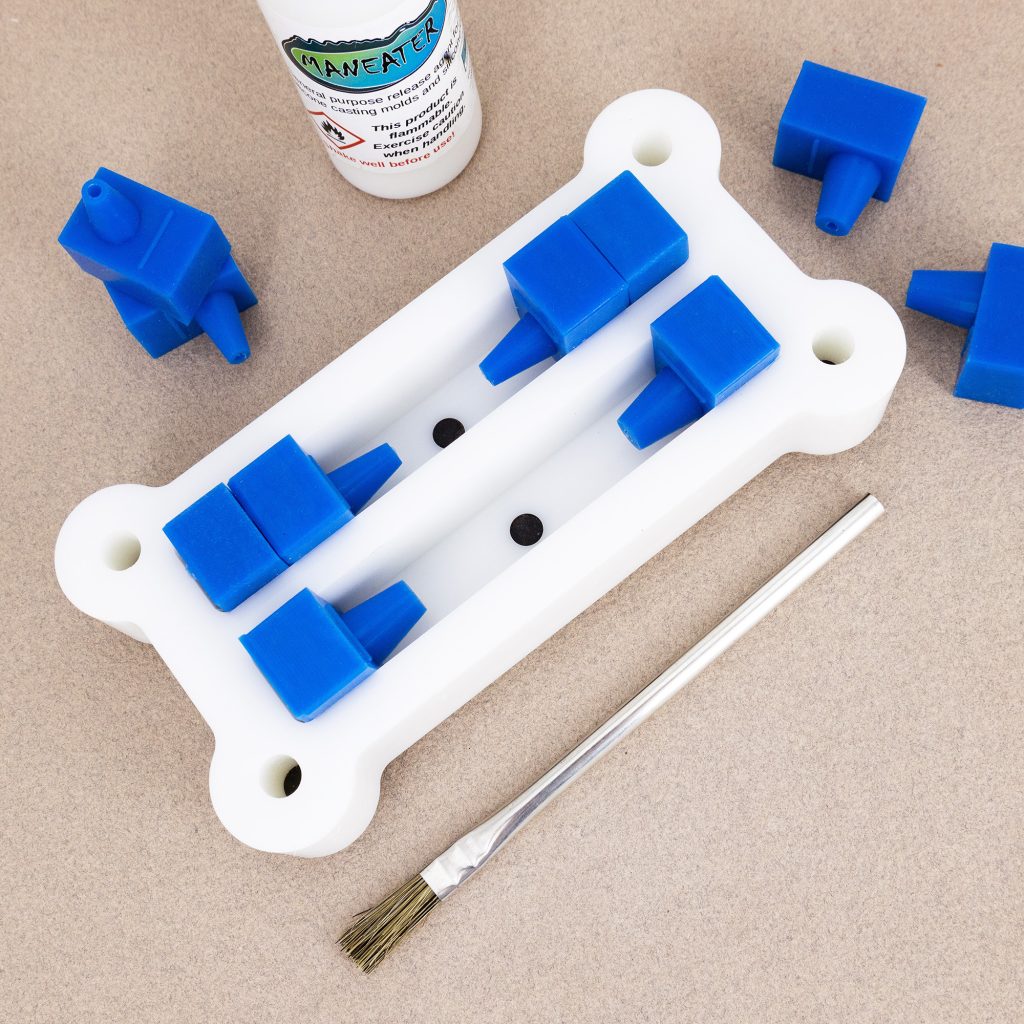

Caring for silicone molds

If you put a little bit of effort into taking care of your silicone molds, they’ll last a long time and be worth every penny.

- Use a mold release spray. Mold release sprays create a barrier so your cured resin will pop out easily. The spray you use depends on the casting material rather than the mold itself. We recommend Stoner Thermoset for Polyester and Epoxy Resins, and Stoner Urethane for urethane resin like Alumilite. Release sprays help your mold last longer and prevent frustrating mistakes.

2. Clean between uses. Taking a minute to wash your molds with gentle dish soap and a sponge will make them last longer and ensure there are no leftover bits of resin that might ruin your next project. Just make sure they’re 100% dry before casting again. Some people also wipe their mold out with a bit of acetone on a cloth.

3. Store properly. Keep your silicone molds in a cool dry place. Silicone can absorb moisture, which will interfere with your finished product. Store them away from sunlight and be sure they’re kept completely flat. If they are left bent or squashed, they will lose their shape.

4. Keep an eye out. Every so often, have a close look at your mold before casting to make sure there are no imperfections. If it seems brittle or gets lighter in colour, it’s time to replace it.

Check out our handmade resin pen blanks for inspiration

At William Wood-Write we’re always creating new pen blanks in many designs and colours. Our in-house-made Fusion/Hybrid pen blanks are among our most popular options for wood turners. Homemade resin pen blanks make the most unique pens and other turning projects out there, whether you sell at markets, online or just want to make gifts. We have everything needed to get casting, including mica powders for colour, glitter, resin, molds and tools. Don’t forget to sign up for our newsletter to find out what’s on sale, new or back in stock!