Have you ever wanted to repair a handmade pen, but weren’t sure how to safely disassemble it? Or maybe you’ve applied a glossy CA finish and ended up with your bushings covered in glue. These are common pen turner problems, and there are specialized tools to help deal with them. In fact, there’s a pen-specific tool on the market for nearly everything to help streamline your process, perfect your set-up and address almost any pen turning issue you can think of. While it’s certainly possible to make beautiful lathe projects with basic tools, these just make the tricky parts a little bit easier.

Tools for making pens on a lathe

Turning wooden pens is a more involved process than many people realize. Unless you’re fully immersed in the craft, you may not be familiar with some of the tools of the trade. These tools help create pens of the best quality with fine attention to detail and take your work to professional levels. They also prevent frustrating mistakes and wasted materials.

Pen Assembly/Disassembly Press

An assembly/disassembly press allows you to safely press your pen kit parts together without damage. It can also safely pull finished pens apart. While many pen makers use the lathe itself to assemble pen kits, this tool does that and more. It allows for steady control and accuracy, eliminating the chances of damage. It’s also great for taking pens apart to repair them or touch up their finish.

- To convert from assembly to disassembly, just remove the plastic “stop” component.

- The assembly clamp provides over 250 lbs. of pressure to firmly and accurately press pen parts together. The spring-loaded ram acts as a third hand for quick and easy parts positioning. The sled mechanism slides the assembly stop into position. A locking lever then securely locks the rod in place.

- While disassembling, the unique ram design easily pushes parts out of the pen tube. The included disassembly rods match nearly all pen tube diameters. A soft grip tube and V-profile protect the components during the disassembly process.

Drilling center vise

The drilling center vise is made specifically to hold a pen blank still while drilling it in preparation for gluing in a tube. The jaws ensure precision when drilling the center of your blanks.

- Just set up the vise once and drill all of your blanks in the exact center.

- There’s no need to change the setup regardless of the blank’s size or shape.

- Holds blanks up to 1-7/8″ square.

- It’s recommended that you place a 2″ by 1/4″ piece of scrap wood beneath the vise to keep the exit hold tidy.

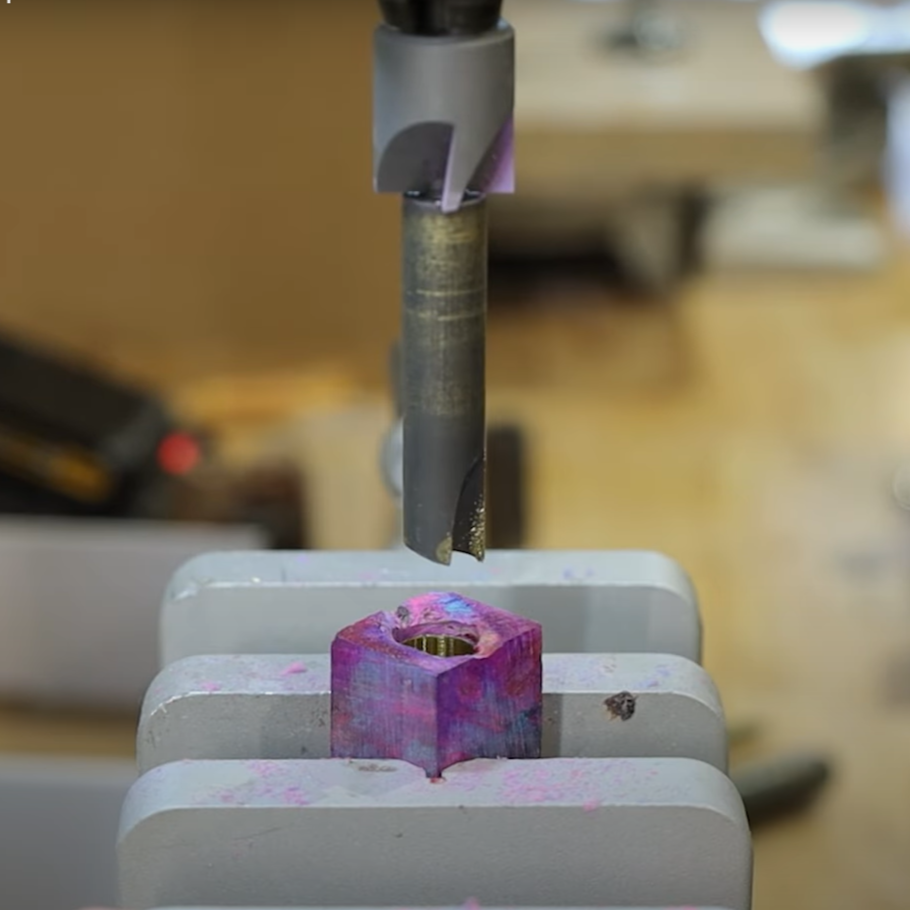

Pen mill and cutter head, aka pilot shaft and barrel trimmer

The pen mill and cutter head (sometimes called the pilot shaft and barrel trimmer) are used to square up the end of a pen blank after it has been drilled and the tube glued in. Pen mills come in different sizes to align with various pen kits, while the cutter head is a standard size and can be screwed onto any pen mill. This mechanism is used on a drill press and makes a perfectly square end in seconds.

- With the pen blank held securely in place, turn on the drill press and bring the pen mill down into the tube.

- The cutter head cuts the pen blank perfectly square while the pen mill pushes all debris out of the pen tube.

- While cutting, go slowly and check the pen blank often to avoid overdoing it. If you go too far, it will shorten the tube and interfere with the pen’s function. Only cut until flush with the tube.

Wood turning tools for fine details

Brad point drill bits. The pointed tip of a brad point drill makes for accurate centering. The chance of blowout is decreased because the point exits first, leaving a neat and clean hole.

Finishing bushings. These bushings are a must-have for finishing with CA glue. Made of Delrin, they are mounted directly between 60-degree centers on your lathe. They let you apply a CA finish without the mess.

Bushing adapters. Bushing adapters make it possible to turn any pen kit between centers without a mandrel. They fit between 60-degree live and dead centers and are compatible with all bushings.

Cutters. Carbide cutters, including beading tips, are mounted to the end of your chisel and help you really get into the details. A negative rake beader makes for a smooth, chip-free experience and is available in different sizes.

The best pen kits and wood turning supplies

Our Canadian warehouse is stocked with every tool of the trade to take your penmaking to a professional level. While you’re on our site, check out our gigantic selection of pen blanks, exotic wood, and pen and project kits. Whether you’re wood turning is a personal hobby or a business venture, William Wood-Write is a small family-owned business that has you covered. Sign up for our newsletter for weekly specials, new products and turning tips.