A Comprehensive Breakdown of Every Finish Offered at William Wood-Write Ltd!

When it comes to finishing pen and project kits, there are seemingly endless options of finishes to choose from, ranging from natural, food-safe waxes to specifically formulated chemical finishes. Whether you are working with acrylic, wood, or anything in between, it can be difficult to figure out which finish is the right one for your project.

So, we’re here today to break down every single finish we offer at William Wood-Write Ltd.! In this article, we’ll outline the how each finish should be used, what materials to use them on, dry time and more!

Pen and Project Kit Finishes

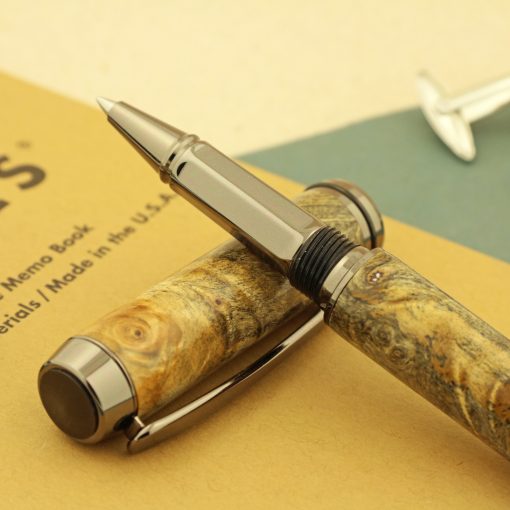

When it comes to finishing pen kits or project kits with relatively smaller parts, it can be tough to figure out which way to go in terms of finishes. For pens, pencils, razors and other projects that will be handled frequently, there are a variety of options that offer a variety of pros and cons.

Aussie Oil

We’re going to begin with a tried and true favourite here at Wood-Write, Aussie Oil!

Aussie Oil is a hard, durable and long-lasting finish and the proprietary formulation makes wood grain pop and brings out amazing depth, brilliance and a high gloss finish on any pen or project kit.

Aussie Oil is formulated as a fusion mixture of hard shellac and, when applied to wood, it traps oil in the matrix of the hard shellac. While you can apply Aussie Oil by hand or on the lathe, it is recommended to apply Aussie Oil while your project is turning on the lathe, as this finish works best as a friction polish.

Dry Time: 1-3 Minutes

Food Safe: No

Designed to be Used on: Wood

Number of Coats: 3-4

Mylands High-Build Friction Polish

Next up is Mylands High Build Friction Polish, which is similar to Aussie Oil in that it is most often applied while on the lathe and creates a high-shine finish on wood grain.

You may be asking: What exactly is “friction polish”?

Friction Polish is a Shellac-based finish designed specifically to be used on turned items on the lathe. The formulation of friction polishes are such that the friction and heat that occurs during the polishing process hardens the finish.

The extremely high shellac content in Mylands High Build Friction Polish means that this finish also builds up nicely, allowing you to create a durable finish without the need for any kind of sealing coat prior to application.

Friction Polishes like Mylands are well-known in the penturning world as convenient one-step finishes that provide protection while creating a high-shine finish on pen and project kits.

Dry Time: 30-45 Seconds

Food Safe: No

Designed for Use on: Wood

Number of Coats: 3-4

Craft Coat

Next up: Craft Coat!

Craft Coat is a wood finish formulated from equal parts 100% pure linseed oil and waterborne urethane, designed to bind at a molecular level, that creates an extremely durable, water and scratch-resistant finish without having to introduce harsh stabilizing solvents.

Given that Craft Coat does not have a solvent base, this finish dries very quickly to provide a glossy sheen to any wood from dense exotic woods to naturally oilier woods.

There are a few different ways to apply Craft Coat: It can be brushed on with a brush, wiped on with a cloth, sprayed on with a spray bottle, or dipped coated! If dipping your blank in Craft Coat, it is recommended to allow the finish to dry for 1-2 hours before lightly sanding and applying additional coats.

We recommend applying Craft Coat like a friction polish to create an easy, durable, gorgeous finish that will last. Simply apply the finish to your blank using a clean shop towel while it is on the lathe, allowing the piece to dry for 30-45 seconds in between coats.

No matter how you choose to apply it, Craft Coat is a dependable and versatile wood finish you’ll surely fall in love with for pen and project kits.

Dry Time: 30-45 Seconds if applying on lathe, 1-2 hours if sprayed/dipped

Food Safe: No

Designed for Use on: Wood

Number of Coats: 3-4

EEE Ultra Shine Polish

Another tried and true finish in the penturning world is EEE Ultrashine Polish; a cut and polish paste wax containing the ultra fine abrasive Tripoli powder, designed to enhance the effect of your sanding (it actually makes a 240 grit sanding sheet function like it is 1200+ grit)!

For plastics and acrylics, EEE Ultrashine is meant to be used as a finish on its own, as the abrasive Tripoli powder serves to not only eliminate sanding time, but also any and all sanding marks on these kinds of materials.

For wood, EEE Ultrashine is meant to be used in conjunction with Shellawax, with EEE serving as a final sanding step of sorts and Shellawax as the sealant and glossy finishing step.

Simply apply an even coat of EEE Ultrashine Polish on your blank while it is on the lathe, buffing the polish into the material with a clean shop towel thoroughly. Then, follow this step with a few coats of Shellawax for a durable, flawless finish on both acrylic and wood pens and projects.

Dry Time: 30-45 Seconds

Food Safe: No

Designed for Use on: Wood, Acrylic (Plastic)

Number of Coats: 1

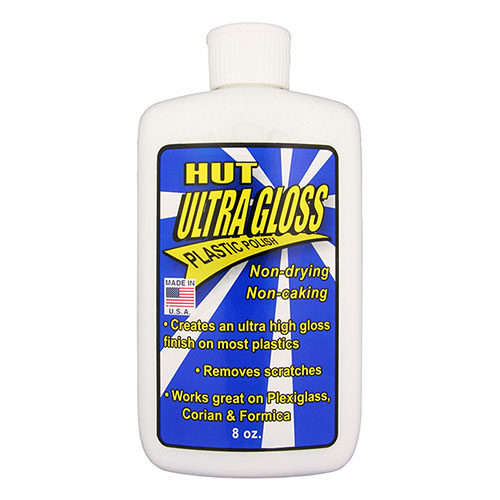

HUT Ultra Gloss Plastic Polish

One of our absolute most frequently used finishes is Hut Ultra Gloss Plastic Polish! This polish is one of the easiest and quickest ways to get a flawless, blemish-free finish on plastic materials (acrylic, lava lamp, glitter, poly resin, etc.) and CA-Glue-sealed wooden pen blanks!

Not only is Hut Ultra Gloss Plastic Polish specifically formulated so that it doesn’t cake or dry during application, you don’t even need to sand past 800 grit to obtain a beautifully glossy finish!

Hut Polish serves as a stunning finishing touch to gloss up acrylic and plastic pen blanks; Simply apply Hut Polish onto your blank while it is on the lathe using a clean shop towel and buff for a minute or more to ensure ultimate shine.

For wood pen blanks: After applying 8-10 coats of Thin CA Glue to your blank and then re-sanding it gently with Micro Mesh Sheets, apply a generous amount of Hut Polish to your blank, using the same method as with acrylics as outlined above, for a glossy sheen on your finished wood piece.

Dry Time: Instant

Food Safe: No

Designed for Use on: Acrylic (Plastic), CA Sealed Wood

Number of Coats: 1

Shellawax Liquid

Shellawax is an easy-to-use, convenient one-step finishing product from Australia made from a mixture of shellac and wax, designed specifically for finishing projects on the lathe. When applied on a pen blank while the lathe is on, this finish is formulated to fuse into the wood via friction, creating a durable, water-resistant finish.

Shellawax is recommended to be used in conjunction with EEE Ultrashine Polish to obtain a completely blemish-free, durable, water-resistant. The microscopic abrasives in EEE Ultrashine work in conjunction with the specific formulation of Shellawax to: Eliminate sanding time, eliminate any and all blemishes, and create a resistant, beautiful finish.

Just work a coat of EEE Ultrashine Polish into your pen or project blank, as outlined above, and follow this by applying Shellawax Liquid using a clean shop towel while the lathe is still running. Using Shellawax to seal and protect your blank after giving it a flawless shine with EEE Ultrashine Polish is a foolproof, convenient and quick way to finish pen and project kits as well as larger projects!

NOTE: Shellawax in its liquid form contains alcohol, making it flammable and poisonous. However, these solvents evaporate once applied, leaving you with a 100% non-toxic, non-flammable finish.

Dry Time: Instant

Food Safe: No

Designed for Use on: Wood

Number of Coats: 2-3

Super Gloss Friction Polish

Another option for finishing wood with a friction polish is Super Gloss Friction Polish! Super Gloss Polish is a lacquer-based finish designed to be applied while your project is turning on the lathe.

Similar to Mylands, Super-Gloss Friction Polish is formulated to be applied to tight grained wood, as a finish in itself or after applying EEE Ultrashine Polish. It dries instantly to a hard, durable, high-gloss finish to protect and beautify your pen and project kits!

For a wet, glossy finish: Apply 3-4 coats of Super Gloss Friction Polish to your blank while it is turning on the lathe AFTER working in a coat of EEE Ultrashine. By using heavy pressure to buff the finish into the wood and allowing a minute or two between coats for curing, you will obtain an extremely high-gloss finish.

For a more satin-like finish: Apply only 1 coat of Super Gloss Friction Polish on your blank in the same way as outlined above, but don’t precede this step with EEE Ultrashine. By using Super Gloss as a finish in itself, you will obtain a slightly less glossy, but still extremely durable, finish.

Dry Time: Instant

Food Safe: No

Designed for Use on: Tight Grain Wood

Number of Coats: 3-4

Food-Safe Finishes

Clapham’s Polishes

For woodturners looking to finish projects that will come in contact with food, like Charcuterie Boards, Clapham’s Wood Finishes are the way to go. Wood-Write carries various versions of Clapham’s Wood Finishes, each designed for slightly different purposes, and we’re here to break down the real difference between Clapham’s Beeswax Polish, Salad Bowl Finish, and Hemp Wood Wax, as well as the best way to apply these finishes.

Clapham’s Beeswax Polish is made with pure beeswax and a bit of carnauba wax to harden the deodorized mineral solvent and, therefore, the shine.

This version of Clapham’s wax has the purest concentration of natural beeswax out of all of Clapham’s finishes, and the deodorized mineral spirit solvent in this polish does not contain the carcinogens that some other finishes do, making this finish completely food-safe and non-toxic.

Clapham’s Salad Bowl Finish is made with organic carnauba wax, pure beeswax and natural mineral oil, which makes this finish even more natural and perfectly suitable for all wooden kitchen tools!

The purity of the components of Clapham’s Salad Bowl Finish means that this finish is also perfect for wooden baby toys and cribs! Apply Salad Bowl Finish the same way you would with Beeswax Polish to obtain a satin-like protective finish on your woodturning projects.

Clapham’s Hemp Wood Wax contains beeswax and carnauba wax, like their Salad Bowl and Beeswax finishes, but uses hemp oil rather than mineral oil for a petroleum-free finish. If you’re a woodworker who prefers to use plant-based oils on your wooden projects, Clapham’s Hemp Wood Wax is an excellent option that eliminates any and all petrochemicals.

Hemp Wood Wax will, however, leave you with a more matte than shiny finish while still providing your pen or project with protection and durability against water damage and staining.

Applying Clapham’s wood finishes is fairly straightforward; To get the products’ full benefits, is recommended to apply a thin layer of Clapham’s finish on your turned piece with your hand, a cloth or a paper towel, and allow this layer to dry before buffing the finish in and re-applying subsequent layers.

Finishes can also be easily re-touched by buffing in a coat of your chosen Clapham’s finish whenever you feel like your project is looking a little dull and dry, making Clapham’s an ideal buildable finish for any kitchen utensil project you may create!

Dry Time: 5 Minutes

Food Safe: Yes

Designed for Use on: Wood

Number of Coats: 1-4 / As Needed

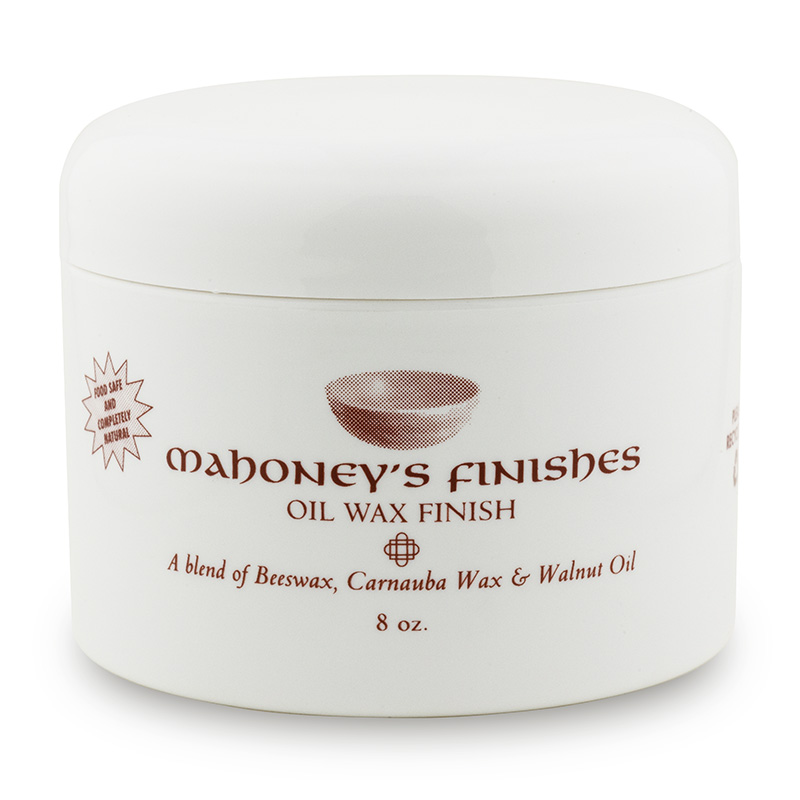

Mahoney’s Utility Oil/Wax Finish

Mahoney’s Food Safe Utility Oil Finish is made from walnut oil and 100% high linoleic acid (an acid that is found in walnut oil and that makes this oil’s shelf life much longer than other natural oils), and includes no chemical dryers.

This means that Maoney’s Utility Oil is completely food-safe, non-toxic and suitable for finishing projects that will come into contact with food, like bowls, plates and other kitchen utensils!

Applying Mahoney’s Utility Oil Finish is pretty straightforward and similar to other finishes;

Apply a heavy coat of the oil on your project, let it soak for at least 5 minutes, and then buff off excess oil using a clean shop towel. Once buffed, your blank will be instantly dry, protected from water and damage, and beautifully finished.

For those who prefer to use a wax finish rather than an oil or liquid finish, Mahoney’s also offers an Oil Wax Finish. Mahoney’s Oil Wax Finish contains Walnut oil in addition to beeswax and carnauba wax, and will leave you with a shiny, beautiful, protected finish when applied using the application method described above!

Dry Time: Instant

Food Safe: Yes

Designed for Use on: Wood

Number of Coats: 1 Heavy Coat, buff off excess

Osmo Finishes

When it comes to natural, food-safe wood finishes, Osmo is another excellent choice! Osmo wood finishes are made with renewable raw materials including soybean, sunflower and thistle oil, and carnauba and candelila wax, making them completely safe for direct contact with food, once dried. Osmo Finishes are ideal for creating stunning finishes that are resistant to water and chemicals, microporous, breathable, non-cracking, and extremely durable and hard-wearing.

We offer 3 variations of Osmo Wood Finishes at William Wood-Write: Polyx-Oil, TopOil and Wood Wax.

All 3 of the Osmo finishes we carry provide extreme durability and resistance against liquid spillages due to their high solid content. However, there are slight differences between Osmo Polyx-Oil, TopOil and Wood Wax that make each finish ideal for slightly different purposes.

Osmo TopOil Hardwax-Oil is designed largely for finishing wooden countertops, tables and other kitchen work surfaces (as opposed to hardwood flooring), as TopOil contains the highest amount of solvent among all Osmo finishes.

The thinner consistency created by the high solvent content makes TopOil ideal for easily finishing wooden kitchen surfaces, such as cutting boards!

Osmo Polyx-Oil Hardwax-Oil wood finish contains less solvent than TopOil, meaning that the final consistency of Polyx-Oil is much more viscous than TopOil.

Polyx-Oil is designed specifically as a topcoat for finishing hardwood floors and other heavily-used wooden surfaces, and this finish can be easily spot-repaired without the need to sand away everything you’ve already finished!

Osmo Wood Wax Finish differs from TopOil and Polyx-Oil in that Wood Wax is designed to penetrate more deeply into wood rather than just coat it.

While Wood Wax is food-safe and protects against liquid spillage, it is recomended to apply a sealing topcoat, such as TopOil or Polyx-Oil, after applying Osmo Wood Wax to fully seal and protect your project.

Applying Osmo Finishes:

The application of OSMO depends both on your own preferences as well as what exactly you’d like your finish to look like. Each of the following applications will, however, leave you with varying degrees of gloss and protection:

Applying by hand with cloth/easy pad:

One of the easiest ways to apply an OSMO finish is by hand using a clean shop towel or an OSMO Easy Pad. It is recommended to work the product into your wood project with the cloth or pad, using circular or figure-8 patterns, and let the oils soak into the wood for 15 minutes. Then, working with the grain, remove all excess product with your cloth or pad and let it dry for 8-10 hours before applying additional coats.

While applying OSMO finishes this way will allow you really enhance the figuring in your wood projects, you may not be able to obtain full durability and stain resistance. For projects that require the utmost protection and durability, like countertops and cutting boards, it is recommended to apply OSMO finishes with a brush or roller.

Applying with brush or roller:

For those looking to create a more protective, durable finish on the surfaces of woodworking projects, like cutting boards or tables, applying Osmo finishes with a brush or roller is the way to go.

We love Osmo’s 25mm Natural Bristle Brush, which is specifically designed for the application of Osmo wood finishes! Made from 100% natural bristles, these high-quality German made brushes are designed specifically for quick and efficient application of Osmo products.

Simply apply one thin coat of Osmo Wood Finish using a brush or roller of your choice, making sure to cover the entire surface you are working with, and allow 8-10 hours for it to dry before applying subsequent coats.

For a more subtle glazing effect, allow the product to sit on your surface for up to 20 minutes before buffing off excess, allowing 8-10 hours of drying time, and applying more coats!

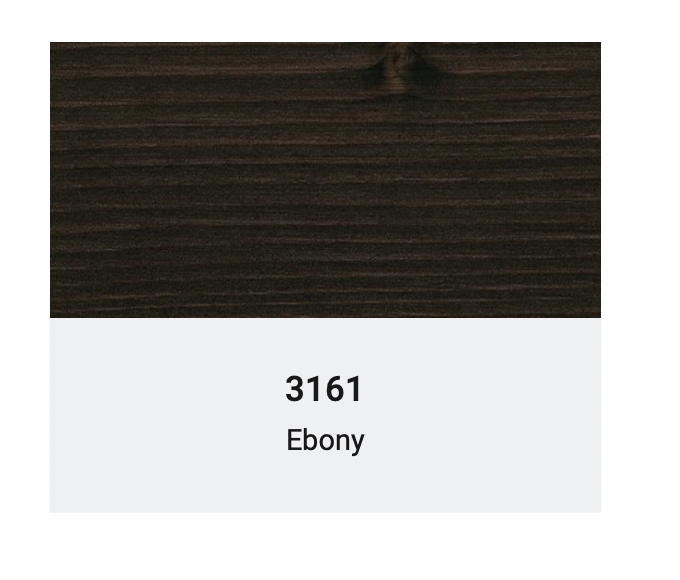

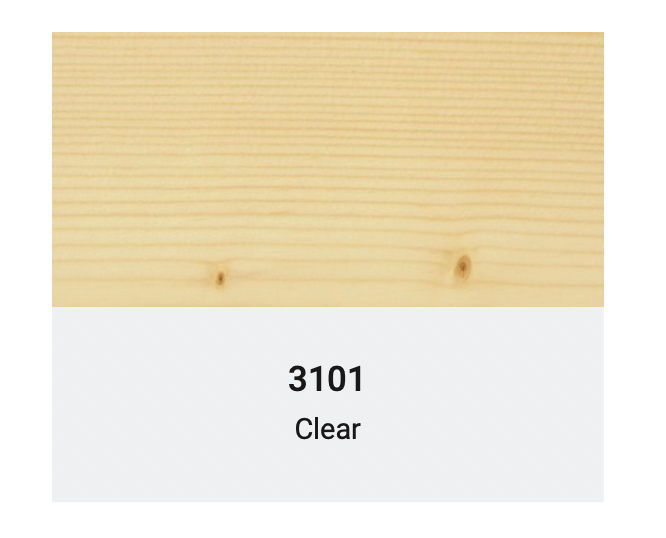

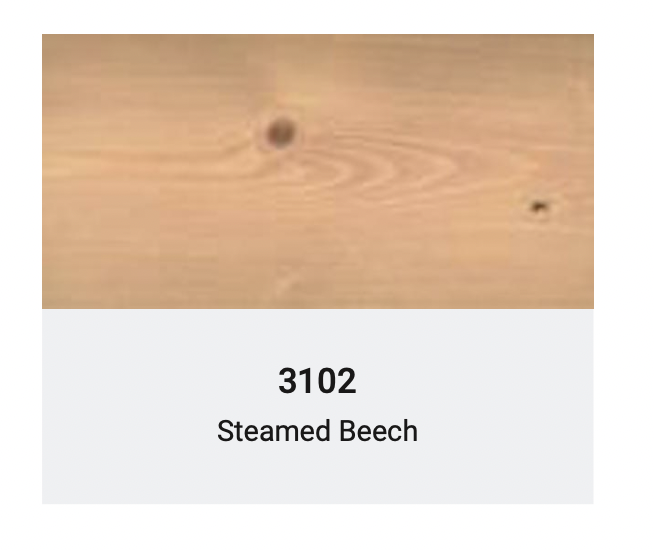

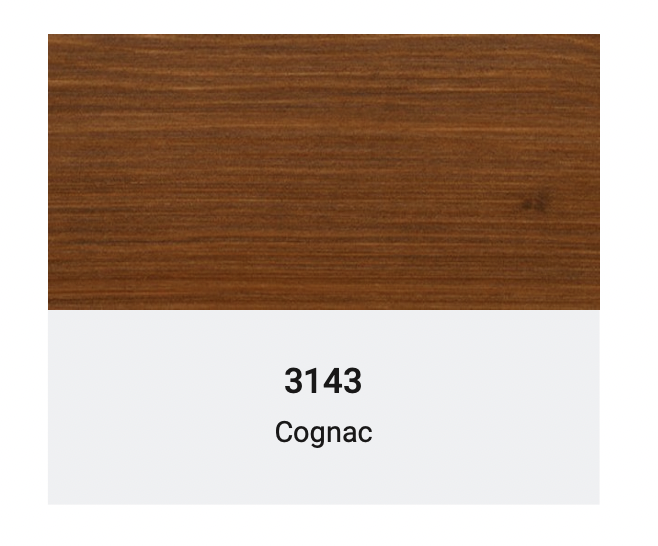

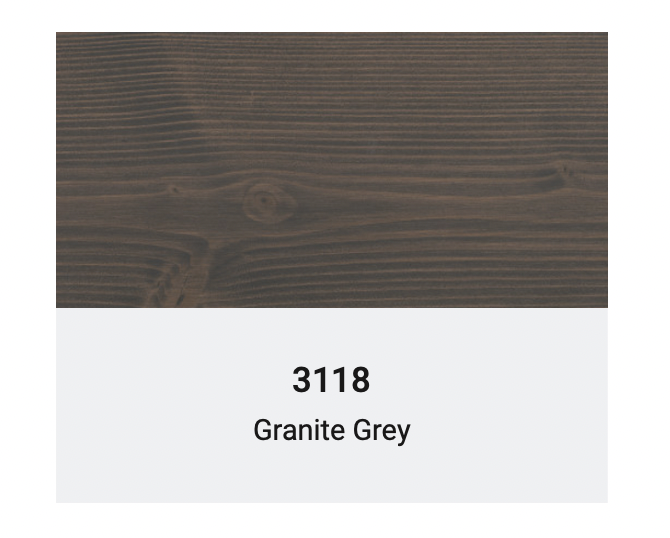

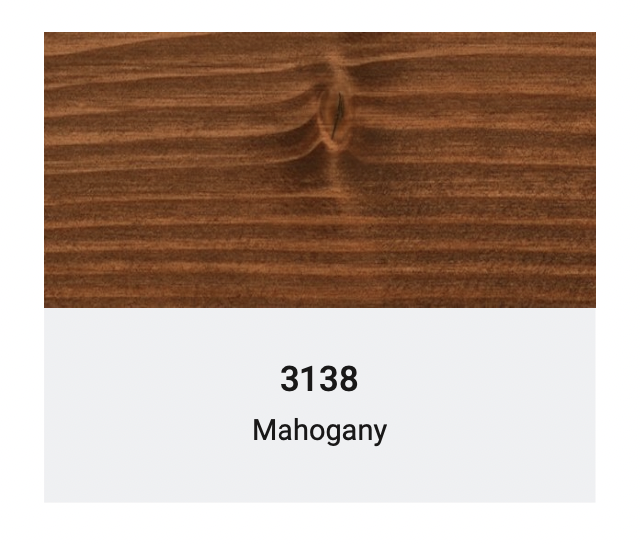

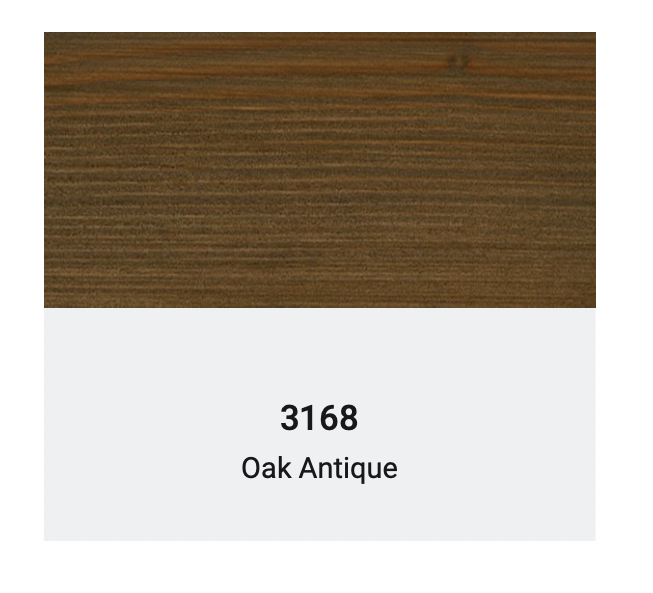

Try Different Colours!

One of the most exciting things about Osmo wood finishes is the sheer amount of options to choose from when it comes to the colour and desired shine of your finish!

Wood-Write currently carries Osmo TopOil in “Clear Matte” and Polyx-Oil in “Clear Matte“, “Clear Gloss” and “Clear Satin“. Whether you’re searching for a high-gloss, wet-looking finish or more of a matte finish, you’re sure to find the perfect Osmo finish for any project in store at William Wood-Write or at penblanks.ca!

When it comes to Wood Wax, there are even more exciting colours to choose from! While Wood-Write does not carry every single colour offered by Osmo, we do carry Osmo Wood Wax in a variety of transparent shades, meant to provide your projects with the superior protection and durability of Osmo finishes, while either concealing or enhancing the wood grain with a tinted stain!

Dry Time: 8-10 hours

Food Safe: Yes

Designed for Use on: Wood

Number of Coats: Roller/Brush = 2, By Hand = 3-6

C-Coat Epoxy Coating

We know that some projects need just a little bit more protection when it comes to finishing. When other finishes don’t quite cut it, CEC CORP C-COAT Crystal Clear Epoxy Coating is the finish for you!

An epoxy coating differs from the rest of the finishes mentioned in this article in that rather than soaking into your wood, epoxy coating finishes use a two-part resin to create a waterproof, glass-like seal on top of horizontal wood surfaces.

C-COAT Epoxy Coating is a self-leveling product designed to create an extremely high-gloss decorative coating on wooden projects and is commonly used for larger projects like bar and table tops, and can even be used on non-wood surfaces such as metal, stone, glass and fibreglass!

Applying C-COAT Epoxy Coating can be tricky and gets easier with practice, but the application instructions are pretty straightforward:

- Measure out equal amounts of C-Coat Resin (Part A) and C-Coat Hardener (Part B) in separate small containers.

- Using a stir stick, thoroughly mix the two parts together, making sure to scrape the sides of your container, for 2 minutes.

- Pour your mixture onto your chosen surface immediately after mixing and spread it out evenly using a brush or roller.

- Surface will be dry enough to touch in 24 hours and fully cured in 3-5 days.

Dry Time: 30-minute work time, 24 Hours to Cure

Food Safe: Yes

Designed for Use on: Wood, Metal, Glass, Fibreglass, Stone, etc.

Number of Coats: 1-2

And, there you have it! From wood wax to epoxy, we hope this comprehensive breakdown of all finishes offered at William Wood-Write leaves you with something you didn’t know before!

Shop these finishes online at penblanks.ca today! Happy turning!

Subscribe to our newsletter to get all the deals! We promise we won’t bother you, only two emails a week on Wednesday & Sunday to enjoy with your morning coffee.