Stabilizing your own wood for pen turning can be a real trial-and-error process. There are so many variables that impact how your blanks will turn out, such as humidity and temperature. At William Wood-Write, we’ve been stabilizing our own pen blanks and project blocks for years and have learned a few tips and tricks along the way to get that perfectly stabilized blank for any wood turning project.

Preparing the stabilizing resin

Cactus Juice is our first choice for stabilizing resin. The large jug comes with a smaller bottle of activator. These must be mixed together before beginning.

- Mix the entire jug and activator together at once. They are the perfect ratio and will last for a whole year once activated. Don’t guess at measurements or try to split it into batches because it will impede the results.

- The bottle of activator may seem light or even empty. It’s not! It is one-quarter filled with activator. Pour some Cactus Juice resin into the bottle, seal and shake it, and then pour this entire mixture into the large jug. This process ensures that all the activator gets into the jug. You may even wish to repeat this to make sure you get it all.

- Sometimes there are little clumps visible in the activated Cactus Juice, but these will dissolve within a couple of hours.

How to dry wooden pen blanks

One of the keys to successfully stabilizing wood is making sure it’s completely dry before beginning. If there is too much moisture in the wood it won’t absorb the resin properly.

- Put your wood in the oven at 220 degrees for 24 hours even if you think it’s dry enough.

- When you remove the wood from the oven immediately seal it in a sturdy zip-lock plastic bag with no air inside. When warm wood is exposed to cool air, it immediately begins absorbing moisture from the air. The bag will prevent that. If there is condensation on the bag after cooling, your wood isn’t dry enough.

- Fresh wood will not dry in the oven. It needs to air dry for several months before it can be prepared for stabilization.

- Never try to stabilize warm wood. The heat will interfere with the way the resin cures. Cool your wood to room temperature completely.

Using Cactus Juice

This where the real action happens. You will place your dried wood into a vacuum chamber, immerse it in activated Cactus Juice and then use the vacuum pump to suck all the air out. As the air leaves the wood the resin takes its place.

- The stabilizing process can take anywhere from hours to days, depending on the size and density of your wood.

- After placing the wood into the vacuum chamber with the Cactus Juice and starting the pump, you’ll see air bubbles coming out of the wood. You must leave the vacuum on until there are hardly any bubbles coming out. The length of time this takes varies depending on many factors, so keep an eye on it.

- To ensure that the resin fully permeates the wood, allow it to sit for twice the time it took to run the vacuum pump. For example, if it took 6 hours of vacuuming, allow it to sit for 12 hours or longer.

Curing the stabilized wood

Once your wood has had a chance to fully absorb as much resin as possible, it’s time to cure it. This will dry the pen blanks so they’re ready for turning.

- Individually wrap the blanks in tinfoil so they won’t stick together.

- Place the wrapped pieces in an oven set at 190 to 200 degrees. Be sure that your oven temperature is correct. Accuracy matters!

- If you’re not sure if your wood is fully cured or not you can very carefully peel back the tinfoil and have a peek but do it quickly so it doesn’t cool down.

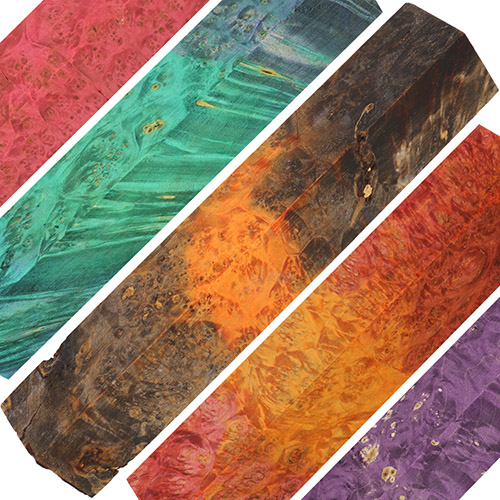

It’s time to turn your stabilized pen blank

Now comes the fun part. Turning your final product. Once your pen blank is fully stabilized and cured, you can mount it on your lathe and start creating that fully custom, handmade lathe project. There’s something especially satisfying in knowing that you have made it from scratch and adjusting the quality to your own standards (and as pen turners, we appreciate those tiny details!). Opt-in to the William Wood-Write newsletter to be the first to know about deals and specials on your wood turning favourites.